Neoflex - PU 25LM Low-Modulus Polyurethane Sealant - Neutral Color 600ml

- View all variations as list

| CODE | Color | Availability | Price | ||

|---|---|---|---|---|---|

|

RI_PU_25LM_W

|

In stock

|

22500 |

Brand: Neoflex

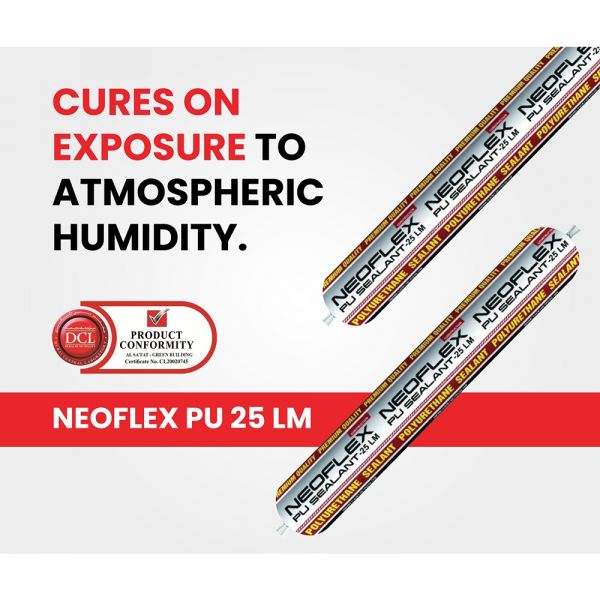

NEOFLEX PU 25-LM is a one-component, low-modulus polyurethane sealant that cures on exposure to atmospheric humidity. Meets the requirements of ISO 11600 F 25 LM, ASTM C-920, ASTM C 719 - Type S, Grade NS Class 25 Use NT, M.A

Properties

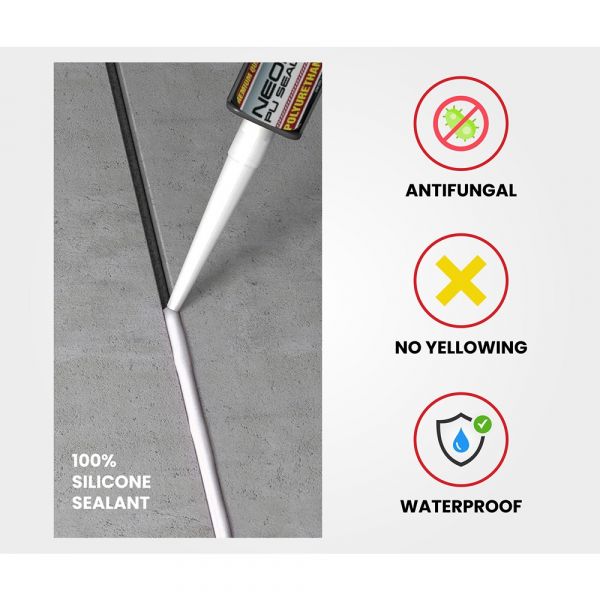

Possesses permanent elasticity

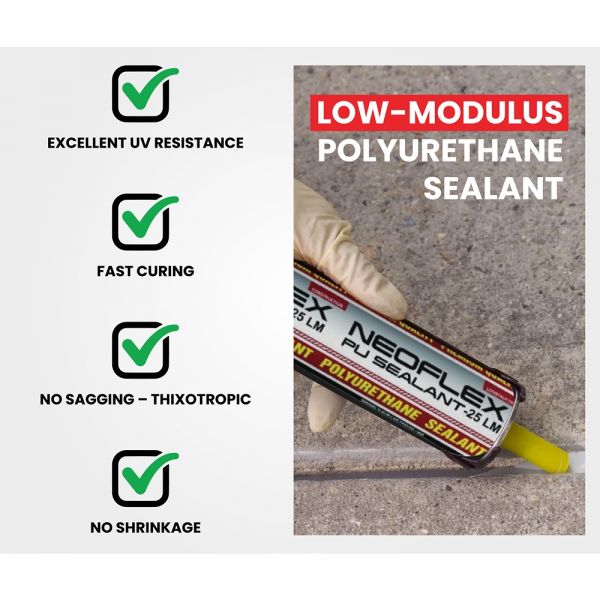

No sagging – Thixotropic

No shrinkage

Excellent UV Resistance

25 % movement capability

Confirms to BS 6920

Suitable for use in Potable water Tanks under special conditions

Paintable Acoustic Sealant

It possesses excellent adhesion to all typical construction materials such as cement based material; brick, ceramic, glass, wood, galvanized and painted sheet iron and certain plastics.

Areas Of Application

Expansion joints between many different construction

materials

Movement and construction joints in floors

Indoor and outdoor applications for pedestrian and

traffic areas

Joints between prefabricated construction materials

Sealing and bonding of ventilation ducts, gutters and

spouts etc.

Excellent Material for sealing joints between pre-cast

concrete panels

Conceal GRC & GRP Lining joints

Method Of Application

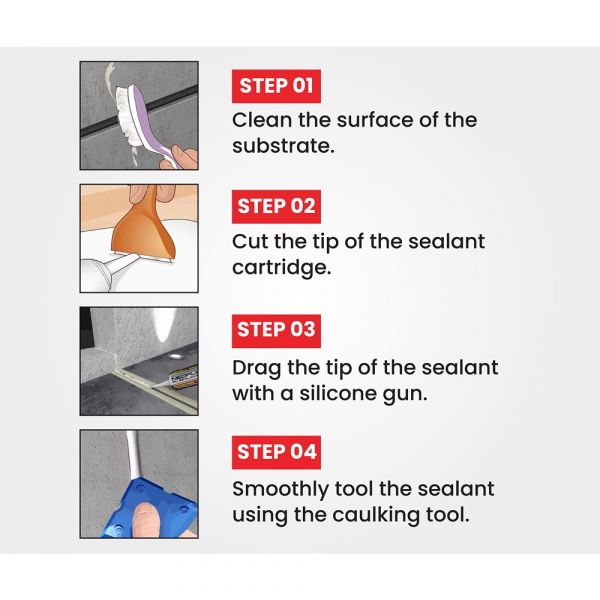

NEOFLEX PU 25 LM sealant shall be applied as per the

following general method of application:

Before application, the joint surfaces should be thoroughly

clean, dry and free of all contamination. Apply sealant

evenly, use masking tape and remove the tape while the

sealant is still tacky.

Joint width/depth ratio should be 2:1

Use a high-density polyethylene backer rod as a backup

material always to adjust the joint width – depth ratio.

Sealants should adhere to only two surfaces of the joint to

take care of thermal expansion and contraction of the joint.

PACKAGING

NEOFLEX PU 25 LM is available in 600 ml Sausage.

Health And Safety

Protective clothing such as gloves and goggles should be worn while applying NEOFLEX PU 25 LM. In case the material splashes to the skin or eyes wash the same with fresh water immediately. In critical cases seek medical assistance.

Storage And Shelf Life

NEOFLEX PU 25 LM should always be stored in dry and covered areas. The product should not be exposed to direct sunlight or be kept near any source of heat. The product Shelf life is up to 12 months when stored as per the recommended storage conditions.

Consumption

Joint Width 15mm 20mm 25mm 3 0mm 35mm

Joint Depth 8mm 10mm 12mm 15mm 15mm

Joint Length/600ml 5m 3m 2m 1.3m 1.1m

Properties Typical Values Test Standards

Color White – Grey Note: special color can be made upon request

Base Polyurethane

consistency Thixotropic

Curing Mechanism Moisture Curing

Density g/ml 1.36

Tack free Time 30 – 60 min (23°C and 50% R.H)

Curing rate Min. 2.5mm/day (23°C and 50% R.H)

Sagging 0mm EN ISO 7390

Temperature Resistance -40°C to +90°C –

Application Temperature +5°C to +55°C

After Curing

Hardness Shore A 32-35 After 28 days (ASTM C661)

Paint ability Yes* -

Elastic Recovery ≥70% ISO 7389

*Considering the diversity of paint base and quality, compatibility tests should be done before application.

Glass

Elongation at Break Min 200% ISO 8339

E100 Modulus (23°C) 0.35-0.40 N/mm² ISO 8339

E100 Modulus (- 20°C) ≤0.60 N/mm² ISO 8339

Dumble Test

Elongation at Break ≥600 % ASTM D412

Tensile Strength 1.5 – 2.0 N/mm² ASTM D412